Borescope inspection on wind turbines

The majority of the energy consumed in the world comes from limited and polluting sources. In this regard, Applus+ is working increasingly on projects focused on renewable energy sources, particularly within the area of wind energy.

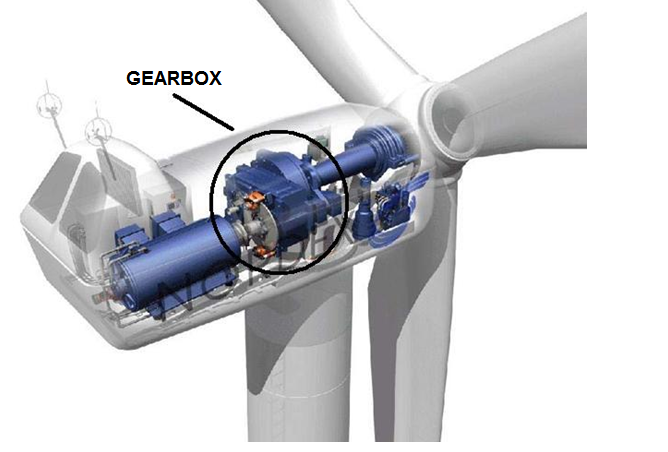

Over the last years, Applus+ Norcontrol in Latam has collaborated in the various stages of constructing wind farms. In this way, one of the most important devices used for wind turbine inspection is the borescope. Wind Turbine’s gearbox borescope inspection is the only way of a full optical inspection of the interior rapidly, accurately and at low-cost.

Gearbox is the most expensive part of the wind turbine and the one that is subjected to the highest loads, especially in sites where the quality of the wind is bad (gusts, high turbulence intensity). Replacement of a gearbox is time consuming and by consequence, leads to reduced availability. Furthermore it can also be extremely costly in case the gearbox is not under any warranty policy.

The wind force acting on the turbine varies depending on the influence of land features, the height from the ground and turbulences caused by changes in the weather. While this variable force imposes a heavy burden on the gearbox, the planetary gear and the planetary stage bearings serve to absorb the varying wind stress. Though the rotating speed is only 20 to 30 revolutions per minute, the planetary gear is subjected to significant stress applied by turbulent airflow. For this reason, visual inspections with borescope are required not only for planetary stage bearings but also for the planetary gear.

Borescope inspection can reveal possible failures and wear in the gearbox parts (gears and bearings) and their root cause. An in time diagnosis is important so that any problems do not grow to a non-treatable condition. Oil analysis can give an indication of the gearboxes’ operational state but cannot provide a full picture of it. In combination with borescope inspection though, it can be a strong tool for the proper maintenance of the gearbox.

This type of inspection should be performed at least once a year. In case that wear or failure are detected, it should be performed more often depending on the problem severity. Borescope inspection is also necessary during the end of contract wind farm inspections for all of the aforementioned reasons.

Borescope inspection can be applied in numerous cases in industrial facilities and other areas such as shipping. It is a reliable way of diagnosing and monitoring faults and functional status of machinery, monitoring and inspecting facilities without the need for long-term cessation of operation or disassembly.

In short, it is an effective decision tool for troubleshooting in industrial and rest of plants and machinery without the risk of significant interventions in their operation.